One of the walls of Dmitry Medvedev's house is decorated with the image of the T-330 bulldozer. Since on September 16, 2016, he received from Vladimir Putin as a gift for his 51st birthday a painting by Nikolai Ovchinnikov "In the workshop", which depicts this particular tractor. By the way, the heavy industrial bulldozer "T-330" can rightfully be called a successful experience of Soviet "import substitution" (a fashionable word in the second half of the 2000s). Everything about the history of this model, its design, technical features and applications is in this article.

In the early 70s of the twentieth century, a number of large-scale projects were actively implemented in the Soviet Union - for the laying of oil and gas pipelines; railways, large industrial facilities, land reclamation. The need for powerful, energy-rich equipment up to the 25th traction class has increased significantly.

Developed in 1972-1975, "T-330" became a worthy replacement for the previously purchased for hard currency similar imported equipment concerns "Caterpillar", "Komatsu", "Liebherr". The task was to stop subsidizing the foreign economy, buying the necessary equipment for foreign currency, and start its own production.

Since the "T-330" was created as an alternative to foreign energy-rich technology, it was naturally developed with an eye to these samples. But there was no exact copy of units and details. As a result, the bulldozer turned out to be somewhat inferior to its eminent counterparts in performance. However, the price of its production and further maintenance was much lower.

As conceived by the designers, the "T-330" was to become not only a heavy industrial bulldozer, but also a prototype, the basis for a new family of industrial tractor platforms, which included machines of various traction classes with a single layout; unified in units and mechanisms. In addition to the main application in cutting and moving soil, "T-330" was intended to become the basis for the creation of a number of carrier units attachments: crane, excavator, pipe-laying.

I must say that this powerful tractor has attracted increased attention from funds mass media, public organizations and foreign specialists long before their mass distribution in the country. The reason for this was the new, unusual design of the model, atypical for standard tractors-bulldozers. Among specialists (not only foreign, but also Soviet), it caused an ambiguous reaction and real disputes.

At the first glance at the "T-330", an unusual and even its layout was immediately evident. The driver's cab, at the behest of the designers, was carried far ahead and installed almost close to the back of the blade. She literally hung right over the blade. This is especially evident on early series bulldozers.

In the process of test operation in the city of Cherbakul, Chelyabinsk region, it was revealed that rock, when developed by a bulldozer, could accumulate on the dump, and then roll over the visor, falling on the front of the cab. And if the work was carried out with rocky soils, then this could lead to damage to the front glass and the cab itself. It did not work to completely secure the cabin by installing a grate made of welded rods.

As a result, subsequently, on the serial versions, the cab was moved back a meter, and an armored hood with the logo of the Cheboksary industrial tractor plant was installed in front of it. But even after the described revision "T-330" still significantly differed in its bold appearance from the standard models of bulldozers of that time.

The idea to implement this unusual layout was driven by the following fact. The main "tool of labor" of a tractor-bulldozer is a bulldozer blade, suspended frontally. With a standard layout behind the massive hood of a powerful and voluminous engine, the operator simply cannot see the workflow in all its details.

This negatively affects his fatigue and reduces his overall work efficiency. And on some powerful bulldozers, the machine operator generally had to work while standing. Therefore, the decision of the Soviet designers to move the cockpit forward turned out to be truly bold and justified. It made it possible to improve visibility, and, consequently, indicators of the accuracy of work, its safety.

In the modern era, "T-330", already under the name "CHETRA-T25", continues to be produced at the Cheboksary Tractor Plant, which is part of the "Promtractor" holding. However, this modern analogue of the T-330, the CHETRA T25 bulldozer, uses diesel engine "QSX15-C440", from the "Cummins" company (in a number of batches - Yaroslavl "YAMZ-8501.10"), and pumping units from the "David Brown" company.

Scope of application and technical characteristics of "T-330"

Heavy tractor "T-330 P1-01" (factory index) is designed for cutting, loosening and moving soils of density levels from the first to the fourth; for leveling the surface of the developed working platform. This bulldozer finds practical application in the following main jobs:

- Development of the surface of the site in layers, movement of ground mass removed from the surface, as well as gravel and crushed stone materials within the working area;

- Filling of trenches, pits and other excavations;

- Planning works, leveling of working sites according to design marks;

- Formation of bulk structures: dams, dams, foundations of highways and railways;

- Warehousing and movement of non-metallic building materials;

- Equipment of pits for the construction of foundations of large objects;

- Clearing areas, with uprooting shrubs and small forests;

- Dismantling and demolition of old buildings, reinforced concrete structures.

In production "T-330" was equipped with a 22.6-liter 8-cylinder 4-stroke diesel engine "8DVT-330A", produced by the Volgograd Motor Plant. The power of this V-shaped turbocharged power plant is 250 kW / 330 horsepower. (By the way, the name of the tractor "T-330" "originated" from this indicator). The cooling system is air, not liquid, well suited to work in the Far North and similar harsh climatic zones.

Cylinder diameter and piston stroke of the 8DVT-330A engine - 150 × 160 mm; rated speed (torque) - 1 700 rpm; specific fuel consumption - 230 g / kWh; high pressure fuel pump - "Bosh" (Germany), "Motorpal" (Czechoslovakia) or "YAZDA" (Soviet Union); maximum tractive effort of the T-330 bulldozer with the 8DVT engine - 670 kN / 68.2 tf; the mass of the 8DVT-330A motor is 2.6 tons. The motor is located in the middle of the tractor, behind its cab.

In fact, during intensive operation, the 8DVT engine served (at best) no more than 3 years, after which it required overhaul... The total resource of this motor was no more than 3-4 thousand operating hours. During the overhaul of the 8DVT engine, all defective units and parts were replaced; grinding the crankshaft to the nearest size or replacing it; installation of new liners, piston rings; tuning, adjustment of fuel equipment; replacement of all seals, rubber goods; installation of new harnesses, sensors; replacement of the starter ST-721, alternator 11.3701.

In the "dashing nineties" the Volgograd Motor Plant (like many other enterprises in Volgograd, and other cities) underwent total ruin and plundering, and this engine model "made it live a long time." Therefore, many owners of bulldozers got out of the situation by changing the 8DVT-330A engine, which had completely exhausted its resource, to the BelAZ engine "YaMZ-240 NM2".The few "survivors" and "remaining in the ranks" of the T-330 tractor, for the most part, are no longer equipped with their "native" Volgograd engine, namely the Yaroslavl "YaMZ-240".

Overall dimensions and other characteristics of the bulldozer in figures

- Length x Width x Height - 9.330 x 4.762 x 4.230 (through the exhaust pipes) meters;

- Gross weight - 42 tons; Specific ground pressure indicator - 0.57 kgf / cm2;

- Ground clearance - 570 mm;

- Fuel tank volume - 670 liters;

- Speed \u200b\u200brange, forward - from 0 to 16.7 km / h, back - from 0 to 13.7 km / h;

- Effort - sinking 15 300 kg, lifting 56 400 kg;

- Traction class - rated thrust: 25 t, maximum thrust: 66 t.

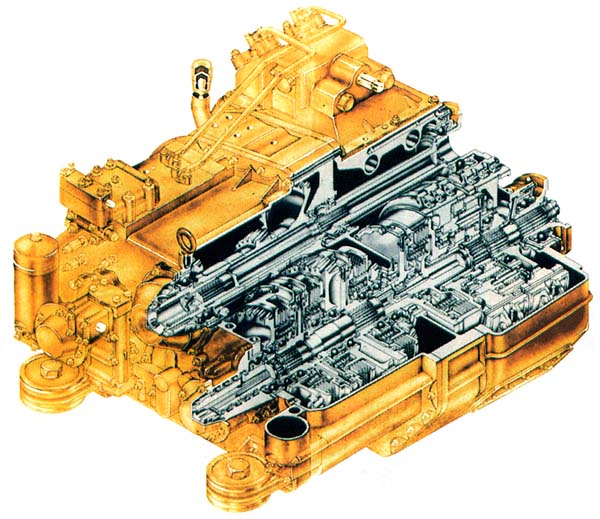

The welded frame of the tractor is assembled from a pair of steel box-section spars, which are connected by cross members in the front, middle and rear parts. A balance beam is fixed in front, supported by tracked carts. Suspension type - elastic, with a balance bar.

The running system is semi-rigid, assembled from two tracked bogies. The axles of the final drives, on which the bogies are supported, allow them to swing. The bearing assemblies of all rollers and wheels contain an “eternal” lubricant, which ensures the operation of the mechanisms for the entire period of their operation. Support type rollers 14. The hydraulically driven mechanism allows to ease the tension of the track. The caterpillar track is detachable and consists of 42 shoe links, with a pitch of 250 mm. The link width is 650 mm, the contact of one track with the soil is 4.86 square meters.

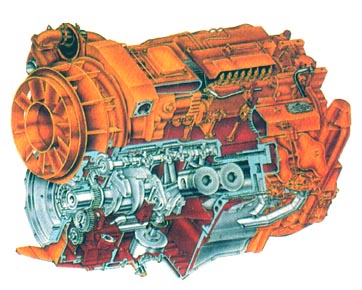

The hydromechanical transmission "T-330" is equipped with a three-speed, fully reversible gearbox, which separately transmits torque to both sides. Separately, the brake system also operates, which, together with the reverse, ensures the maneuverability of the bulldozer in a confined space (allows it to turn in one place).

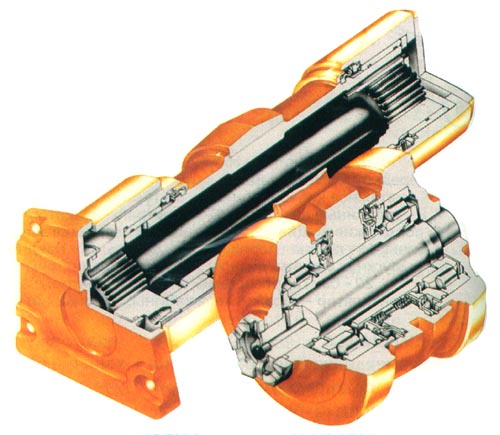

Two-stage side gears: external gears interact with the planetary assembly, the carrier of which is braked. The drive wheel sprocket assembly is bolted for easy replacement. The torsion bar suspension of the rollers is designed to improve ride comfort and minimize dynamic loads.

The hydromechanical transmission allows you to effectively use the engine power at any speed of the tractor, including developing maximum traction in the stop mode. The tractor gearbox provides an independent drive of each track with the possibility of its reversal, which allows making turns in confined conditions. The torque converter of the T-330 tractor is based on a similar unit of the TGM-1 diesel locomotive. Brakes - band, floating type, supplemented by hydraulic control. Hydraulic equipment - high-capacity hydraulic pump, remote controlled valve.

An increase in the practical efficiency of the T-330 bulldozer when working on a frozen surface is achieved, among other things, due to the ability to divert exhaust gases under the dump. That prevents the conglomerate of soil from freezing, which can reduce the mobility of the bucket and the mass of the material being moved. Thanks to the efficiently implemented air-cooling system, the engines are designed for cold starts even at extremely low temperatures.

Characteristics of bulldozer and ripping equipment

Dump: (knife, hemispherical type): length 4.860 m; height 1,820 m; capacity: 13 cubic meters; dump depth: 1.530 m; weight: 7 tons.

Ripper: single-tooth, lifting height - 950 mm; maximum depth - 1380 mm; maximum penetration force - 15.3 t; maximum pull-out force - 56.4 t; weight - 6.5 tons.

The cab of this tractor is also designed specifically to work in the harsh northern conditions. It is reliably sealed, equipped with a powerful heating, ventilation and air cleaning system. The cabin is two-seater, sprung with shock absorbers. The seats are adjustable in tilt angle. The glass of the cabin is glazed in two layers, with reliable protection against icing. Pedals and control levers are conveniently located for the operator, ergonomics are at a height. This massive tractor can be driven without much physical effort. The way of steering control is a separate drive of the tracks.

The tractor is equipped with an original eight-cylinder four-stroke diesel engine with a V-shaped arrangement of cylinders, turbocharging and air cooling, which makes it easy to start at ambient temperatures down to -40 ° C. Cooling - gallery type. The piston bases intensively dissipate heat, which extends the piston overhaul period. Valves for uniform wear of the working surfaces of the valve mechanism are equipped with swing mechanisms. Air purification system - two-stage, with cyclone and filter with paper elements.

The design of the hydromechanical transmission with separate drive to the wheels is modular. The torque converter is a single-stage three-wheel complex with a centripetal turbine. Opaque torque converter with 480 impellers mm, maximum transformation ratio Ko \u003d 3.0 and maximum efficiency. \u003d 0.906 ensures the use of the maximum engine torque and its stepless regulation depending on the loads on the working bodies.

The hydromechanical transmission consists of a six-shaft three-speed, fully reversible gearbox (KP) with helical gears of constant engagement, hydraulic disc clutches of transmissions and a reversible control mechanism for the system of hydraulically controlled band stopping brakes and reverse brakes for each side, structurally combined in one autonomous unit, as well as matching gearboxes of mechanical transmissions for each side. The transmission of torque from the gearbox to the bevel gearboxes is carried out by cardan drives. The gearbox provides a bifurcation of the power flow to the drive wheels, which allows the tractor to turn on the spot due to the different direction of movement of the tracks.

The final drive is two-stage, the first stage is external gears, the second stage is planetary (with the carrier stopped). To facilitate field replacement, the drive sprocket is made up of bolted sectors.

Technical characteristics of the T-330 tractor

| Tractor type | caterpillar, industrial |

| Maximum tractive effort, kN (tf) | 670 (68,2) |

| Engine brand | 8DVT-330A |

| Engine's type | turbocharged diesel |

| Engine power, kWh (h.p.) | 259 (352) |

| Speed \u200b\u200brange, km / h: | |

| .. forward | 0 - 16,4 |

| .. back | 0 - 13,7 |

| Number of transfers forward (backward) | 3 (3) |

| Transmission | hydromechanical |

| Track suspension | elastic with balance bar |

| Specific pressure of caterpillars on the soil, kgf / cm2 | 0,57 |

| Ground clearance, mm | 570 |

| Weight, kg | 25000 |

| Cab location | front |

Brakes - floating band type with hydraulic control, cardan drives of open type with needle bearings.

The main transmission is single-stage with bevel gears. This arrangement of the transmission was later used on almost all powerful industrial tractors.

The semi-rigid undercarriage consists of two track bogies that swing on the axle of the final drives. Track rollers and carrier rollers are attached to box-section crawler carts. The running equipment consists of two tracks, each with five support and two carrier rollers, and a tensioning mechanism. The torsion bar suspension of the road wheels improves ride comfort, reduces dynamic loads and ensures that all road wheels remain in contact with the ground. This makes full use of tractive effort and improves off-road capability.

| Elastic torsion bar suspension of the road wheels of the T-330 tractor |

Track rollers, carrier rollers and idler wheels - with one-time, "permanent" lubrication for life, with self-tightening DUOCONE seals. Track chain tensioning is simplified by hydraulic tensioning mechanisminstalled in conjunction with the delivery mechanism. Caterpillar - sealed and lubricated for life, with a split master link.

The working area is clearly visible from the double cab, sprung with rubber shock absorbers, with heat and sound insulation, and fresh air ventilation. The elastic suspension seat is adjustable for load, height and tilt at the back. The ventilation unit is equipped with a hot air heater. Double-layer glazing protects windows from icing in winter. Conveniently located control levers and pedals, electro-hydraulic transmission control system reduces effort on the controls.

Tractor T-330 ("three hundred and thirty") is a heavy industrial tractor. The model was intended for production earthworks, was used in land reclamation, mining and construction in harsh climatic conditions. The model was produced since 1975 at the Cheboksary industrial tractor plant.

The T-330 turned out to be the object of increased attention from public organizations, foreign experts and the media even before its mass distribution in the country. First of all, the new design of the model was unusual, not typical for standard tractors. Among experts, it caused a different reaction.

When examining the T-330, a strange layout immediately caught the eye. Directly above the dozer blade, the driver's cab hung, which, according to the developers' idea, was carried far ahead, setting it almost close to the back of the blade. On prototypes, this innovation was seen especially clearly. During the tests in the city of Cherbakul, it was revealed that the rock developed by the bulldozer eventually accumulated on the dump, and then rolled over the visor, falling on the front of the cab. When working on rocky ground, this could damage the cab and glass. It was not possible to protect the cab by installing a grill made of welded rods. As a result, on serial versions, the cab was moved back a meter, with an armored hood with the CHZPT emblem installed in front of it. However, even after the revision, the T-330 differed significantly from the standard models of that time. This placement was due to the fact that the main tool in the tractor was a dozer blade, suspended frontally. The operator simply could not observe the working process behind the massive hood with the standard layout. This affected his fatigue and reduced his efficiency. So, on older versions, the driver had to work while standing. All this prompted the developers to bring the cockpit forward. The solution turned out to be truly revolutionary. It also made the technique more assertive and powerful.

The first batch of T-330 in the media received a flurry of criticism. Journalists called the purchase of new items economically unprofitable and talked about the imminent curtailment of the project. However, soon the T-330 had many supporters who proved that in some cases this tractor is much better than the products of foreign manufacturers CATERPILLER and KOMATSU.

T-330 bulldozer video

The model was originally developed with the aim of creating competition with imported equipment. The T-330 made it possible to abandon the purchase of expensive pipelayers, bulldozers and rippers, the maintenance and repair of which cost a pretty penny. The Soviet economy worked for competing states by purchasing foreign equipment. The confrontation between the T-330 and KOMATSU was so fierce that, as part of one of the disputes, the drivers even decided to push the models into literally the words. As a result, the Cheboksary product quite easily “rolled off” the Japanese version.

On the basis of the T-330 tractor, the T-330R1-01 bulldozer with a ripper was later created. It was intended for the development of frozen and durable soils.

The T-330 was equipped with a 22.6-liter 8DVT-330A diesel engine manufactured by the Volgograd Motor Plant. The power of the installation was 250 kW (330 "horses"). The model worked in climatic zones with air temperatures from +50 to -50 C.

- Fuel consumption in the T-330 was 230 g / kW. in hour.

- The volume of the fuel tank is 670 liters.

- The indicator of the specific pressure on the ground is 0.57 kgf / cm2,

- The ground clearance is 570 mm.

- The dimensions of the T-330 are 9330 by 4762 by 4230, weight - 25 tons.

- The range of speeds of the model backward - 0-13.7 km / h, forward - 0-16.7 km / h.

Device

The T-330 was equipped with a four-stroke, diesel, 8-cylinder air-cooled engine. This allowed

operate the tractor at low and high temperatures.

The hydromechanical transmission maintained the effective maximum power of the engine at any speed, allowing maximum thrust to be achieved in the stop mode. Cramped conditions were not a problem for the T-330, since the model's gearbox provided independent drive to the tracks with the ability to reverse. The T-330 received a torque converter developed on the basis of a similar device for the TGM1 locomotive.

The model had floating type band brakes, supplemented by hydraulic controls. The semi-rigid chassis consisted of two tracked vehicles swinging on the axle of the final drives. The torsion bar suspension of the rollers increased the ride comfort and minimized dynamic loads. In the T-330 units, "eternal" lubrication was used.

The cabin of the model is two-seater, with heat and sound insulation. It is provided with fresh air ventilation and is sprung with rubber shock absorbers. The ventilation unit received an air-heater type, and the seats were adjusted for tilt angle, height and load. Thanks to double-layer glazing, the glass was reliably protected from icing. The pedals and control levers were well positioned. The massive tractor could be driven without much effort. At that time, even the owners of other cars envied the comfort and decoration in the cockpit. For the first time, side, rear and front lights were used on the tractor, which did not make it a problem to work in the dark.

The design of the tractor itself met the world level of the 70-80s and had a huge potential for further improvement.

A photo

![]()

The cost

The price of the T-330 tractor, taking into account its size, power and functions, has never been small. Currently, it will not be possible to buy this model in a normal state for less than 3.5 million rubles. The average price range for the T-330 is 3.5-5 million rubles.

Analogs

The analogue of the T-330 caterpillar tractor is the T-330R1-01 bulldozer, created on its basis. This is a more advanced model designed to work in specific conditions.

Other analogues of the T-330 tractor are the T-25.01 bulldozer, the DZ-94S bulldozer.

Introduction

Bulldozer - a self-propelled earth-moving machine, which is a tracked or wheeled tractor, tractor, etc. with a mounted working body - a curvilinear blade (shield) located outside the chassis of the machine. Serves for layer-by-layer digging, leveling and moving (at a distance of 60-300 m) soils, minerals, road-building and other materials in the construction and repair of roads, canals, hydraulic engineering, etc. structures.

History of development

In 1929, the very first bulldozer appeared - a huge and noisy machine. They were made on the basis of tractors by mounting a metal plate in front, unlike a bulldozer, tractor machines appeared even earlier already in the 19th century and were steam-powered. So, back in 1850, the English inventor William Howard used a locomobile for plowing. In the second half of the 19th century, about two thousand of these machines were already working in the fields of Great Britain. The first crawler tractor was built in Russia by a peasant Fyodor Abramovich Blinov, a native of the village of Nikolskoye, Volsky district, Saratov province, in 1879 he received a patent ("privilege") for "a car with endless rails for transporting goods on highways and country roads." This device was powered by a 20 horsepower steam engine. However, this tractor did not become in demand either in industry or in agriculture, and things did not go beyond the prototype of tractors in Russia.

In 1896, the first tractor with an engine was created by American engineers Hart and Parr. internal combustion... Since 1901, these tractors have been on sale. Initially, farmers willingly bought them, but soon the new machines began to cause complaints: they were very heavy and therefore compacted the soil too much. Moreover, they were too large for an average farm. Tractors also suffered from "childhood illnesses": they often broke down, and repairs were long and expensive. However, in 1907, a new tractor model appeared on sale, devoid of the shortcomings of its predecessor. By that time, a system of tractor repair shops began to be created in America.

In 1912, Holt-Parr began producing tracked tractors.

The first Soviet tractor "Kommunar".

In Russia, only Soviet government after 1917, allocating money for the construction of tractors in the difficult years of the intervention for the country. Since 1918, at the direction of V.I. Lenin is preparing production for the production of tractors. In 1919, the inventor Ya.V. Mamin created the Gnome tractor with an 11.8 kW oil engine. The production of tractors was so important that the Decree of the Council of People's Commissars of April 1, 1921 was issued on the recognition of agricultural engineering as a matter of extraordinary state importance. In 1922, the Kolomenets-1 tractors designed by E.D. Lvov. In 1922-1923, the Zaporozhets tractor was created under the leadership of engineer L.A. Unger. In 1924, the Kommunar tractor began to be produced at the Kharkov steam locomotive plant. In 1924 the production of tractors "Dwarf" designed by Ya.V. Mom's engine with a power of 8.8 kW (12 hp), in two versions: tractor "Karlik-1" (three-wheeled, with one gear forward, with a speed of 3 ... 4 km / h) and "Karlik-2" ( four-wheeled, with one gear and reverse). From 1924 to 1932, the Leningrad plant "Krasny Putilovets" mastered and produced about 50 thousand Fordson-Putilovets tractors, and then, from 1934, this plant began to produce the "Universal" tractor with a kerosene engine and metal wheels. The Universal was the first domestic tractor exported abroad.

"Gnome", "Kolomenets-1", "Dwarf", "Zaporozhets", "Kommunar" - the first Soviet tractors. The first tractors were produced in relatively small batches, but thanks to them they taught a lot, educated the first cadres of tractor builders and rightfully entered the history of domestic tractor construction. Further development of the country required the construction of large specialized tractor plants. The following were built: Stalingrad Tractor Plant in 1930 (produced STZ-15/30 tractors), Kharkov Tractor Plant in 1931 (produced KhTZ tractors similar to STZ tractors), Chelyabinsk Tractor Plant in 1933 (produced tracked tractors S- 60). During the ten pre-war years, domestic industry produced about 700 thousand tractors for agriculture. General issue domestic tractors accounted for 40% of their world production. Thanks to these successes in the planned development of the economy, a backward, fragmented agriculture pre-revolutionary Russia has become a large mechanized.

Varieties of bulldozers

1.With a fixed blade, installed perpendicular to the longitudinal axis of the base machine;

2. With a swivel blade, which can be installed in the horizontal plane at an angle to either side of the longitudinal axis of the machine or perpendicular to it;

3. universal with a blade of two articulated halves, installed in the horizontal plane at different angles to the longitudinal axis of the machine or perpendicular to it (track pavement).

Blades of all types of blades are equipped with mechanisms with a hydraulic, rope, or electromechanical drive for lifting and lowering, turning in plan view, skewing in the transverse plane, and tilting forward and backward along the course. B. are supplied replaceable equipment (rippers, slopes, wideners, openers, etc.), expanding the scope of their application and increasing efficiency in certain jobs.

Underground bulldozer - an intermittent mining machine designed for layer-by-layer cutting, scraping and longitudinal movement by pushing - dragging bulk cargo over a short distance, the blade of which has increased control accuracy, is retractable and has a two-way action, and also has increased strength, wear resistance and passability of the structure.

Skidding: TDT-55 - caterpillar skidder Designed for hauling and stacking medium and large timber. Adapted to work in difficult forest conditions.

Produced since 1966 at the Onega Tractor Plant. The model was discontinued in October 2003.

One of those who got under the modernization is Bulldozer DZ-29

Bulldozer DZ-29 based on the DT-75 tractor

Tractor: DT-75 is a general purpose caterpillar agricultural tractor. The most massive tracked tractor in the USSR. As of 1995, more than 2,514,800 units of tractors were built. Production continues at the present time. The industrial modification of the DT-75 tractor is the DZ-42 tractor. Bulldozer-loosening B-10 drawing No. 4 was also modified.

Industrial tractors

Industrial tractors - or industrial tractors. The main purpose of these tractors is their use in industry and industry. Tractors in industry fulfill many functions as they are powerful enough to handle many activities. Also, an industrial tractor is designed to work as a base machine in an earthmoving or construction unit: a bulldozer, a scraper, a pipelayer. The industrial tractor is characterized by the following features:

1. operation throughout the entire service life with the same type of work equipment;

2. work at reduced speeds with high tractive effort in conditions of slipping of the chassis;

3. the ability to work on hard (including rocky soils);

4. the ability to work on waterlogged soils;

5. the need for accurate positioning of the working body relative to the ground;

6. Delivery to the place of work by special transport.

Production

Currently, in 2009, the leaders in the world market for the production of bulldozers are still Caterpillar, Komatsu, Dressta and CHETRA (Promtraktor).

The largest models of bulldozers are presented in the table. 1

Table 1.

| Manufacturer |

Weight, tons |

Engine power, h.p. |

Blade capacity, cubic meters m |

Year of issue |

|

| 27.2 (hemisphere) /34.4 (sphere) |

|||||

| Not known |

|||||

| Not known |

General characteristics of bulldozers

blade length - up to 5,550 mm

dump weight - up to 10 t

blade dimensions: width - up to 6100 mm, height - up to 2200 mm

height with a canopy - 2300 mm

blade lift - 1780 mm

Dump depth - 800 mm

Distance of rock movement - up to 200 m

Engine power - up to 386kW

Weight - up to 58t

Application of bulldozers

Layer-by-layer cutting and digging, leveling, leveling, moving rocks, soil, bulk materials

Press for flexible parts

Or, more simply, bulldozers are needed where a lot of power is needed.

Bulldozer working tools

Push frame

Control mechanism

Loosening teeth, slopes, wideners, flaps (additional equipment)

Description of the caterpillar tractor T-330 (cheboksarets)

T-330 is a heavy industrial tractor brand, manufactured by the Cheboksary Industrial Tractor Plant since 1975. The T-330 tractor was the first in the USSR to have a front cab, which improved the operator's view of the bulldozer equipment. This solution is rarely used on tractors. The tractor has a hydromechanical transmission that makes gear shifting without breaking the torque. The tractor cab is sealed, equipped with a ventilation, heating and air cleaning system, and in the modification for the southern regions it is also equipped with air conditioning.

The tractor engine is diesel, four-stroke, 8-cylinder air-cooled. The use of air cooling made it possible to operate the tractor both at low outside temperatures (up to -45 degrees) and at high temperatures (up to +40 degrees).

Hydromechanical transmission allows you to effectively use the engine power at any tractor speed, including developing maximum traction in the stop mode. The tractor gearbox provides an independent drive of each track with the possibility of its reversal, which allows making turns in confined conditions.

Control of all tractor mechanisms is completely remote and partially automated, that is, all controls located in the cab have no mechanical connection with the actuators. This makes it easier for the driver.

T-330 tractor specification

| front armored hood |

|

| transmission |

|

| caterpillar |

|

| track idler |

|

| tracked vehicle |

|

| track rollers |

|

| cardan transmission |

|

| torque converter |

|

| air filter |

|

| carrier rollers |

|

| leading sprocket |

|

| cabin heater |

|

| main gear |

|

| preheater |

|

| diesel exhaust system |

|

| tool box |

|

| fuel tank |

|

| hydraulic tank |

|

| accumulators |

|

| air fan - cabin humidifier |

|

| hydraulic cylinder. |

The tractor is equipped with an original eight-cylinder four-stroke diesel engine with a V-shaped arrangement of cylinders, turbocharging and air cooling, which makes it easy to start at ambient temperatures down to -40 ° C. Cooling - gallery type. The piston bases intensively dissipate heat, which extends the piston overhaul period. Valves for uniform wear of the working surfaces of the valve mechanism are equipped with swing mechanisms. The air purification system is two-stage, with a cyclone and a filter with paper elements.

The design of the hydromechanical transmission with separate drive to the wheels is modular. The torque converter is a single-stage three-wheel complex with a centripetal turbine. Opaque torque converter with 480 impellers mm , maximum transformation ratio Ko \u003d 3.0 and maximum efficiency. \u003d 0.906 ensures the use of the maximum engine torque and its stepless regulation depending on the loads on the working bodies.

The hydromechanical transmission consists of a six-shaft, three-speed, fully reversible gearbox (KP) with helical gears of constant engagement, hydraulic disc clutches of transmissions and a reversible control mechanism for the system of hydraulically controlled band stopping brakes and reverse brakes for each side, structurally combined in one autonomous unit, as well as matching gearboxes of mechanical transmissions for each side. The transmission of torque from the gearbox to the bevel gearboxes is carried out by cardan drives. The gearbox provides a bifurcation of the power flow to the drive wheels, which allows the tractor to turn on the spot due to the different direction of movement of the tracks.

The final drive is two-stage, the first stage is external gears, the second stage is planetary (with the carrier stopped). To facilitate field replacement, the drive sprocket is made up of bolted sectors.

Transmission of the T-330 tractor

Specification of the transmission of the tractor Т-330

The transmission of the T ‑ 330 tractor consists of a hydrodynamic and mechanical transmission. Hydrodynamic transmissions are divided into torque converters and fluid couplings. The fluid coupling contains two impellers (pump and turbine) and can only change the kinematic gear ratio. The torque converter has at least three impellers (pump, turbine and reactor), the latter must be aligned with the outer support. This allows using the torque converter to continuously and automatically change the kinematic and power transmission ratio between the input and output shafts, depending on the load.

The engine torque is transmitted to the impeller of the hydromechanical transmission either directly or through a matching gearbox.

If a stepped gearbox is used in a hydromechanical transmission, which allows shifting gears without interrupting the power flow between the engine and the drive wheels, there is no friction clutch in this case. If a multi-step transmission is used that performs power-split shifts, the clutch is retained.

The use of hydromechanical transmissions on vehicles contributes to an increase in the service life of the engine, a decrease in the number of stages in the mechanical gearbox and the number of switching, which reduces driver fatigue; improving the cross-country ability and comfort of the vehicle.

However, the hydromechanical transmission in comparison with the stepped mechanical transmission has a lower efficiency, which worsens fuel efficiency car, more complex design, increased weight and cost

Transmission

Transmission (power transmission) - in mechanical engineering, a set of units and mechanisms that connect the engine (motor) with the driving wheels of a vehicle (car) or the working body of the machine, as well as systems that ensure the operation of the transmission. In the general case, the transmission is designed to transfer torque from the engine to the wheels (working body), change tractive effort, speed and direction of movement.

The following requirements are imposed on vehicle transmissions:

ensuring high tractive qualities and machine speed during straight-line movement and turning;

simplicity and ease of control, eliminating the driver's fatigue;

high operational reliability over a long period of operation;

small weight and overall dimensions of the units;

simplicity (manufacturability) in production, ease of maintenance during operation and repair;

high efficiency;

in high-end machines, the requirement for noiselessness is added.

According to the method of transmission and transformation of the moment, transmissions are divided into: mechanical, hydromechanical and electromechanical.

· Mechanical transmissions (simple and planetary) in gearboxes contain only gear and friction devices. Their advantages are in a high ratio useful action (Efficiency), compactness and low weight, reliability in operation, relative simplicity in production and operation. The disadvantage of a mechanical transmission is the stepwise change in gear ratios, which reduces the use of engine power, average speed and agility of the machine. Long shift times make it difficult to operate the machine.

Rigid kinematic connection of the engine with the driving wheels increases the dynamic loading of the engine and transmission, reduces the reliability and durability of the units

The use of mechanical transmissions is typical for Soviet automobile and tank building

· Hydromechanical transmissions have a hydromechanical gearbox, which includes a hydrodynamic torque converter (torque converter, complex hydraulic transmission) and a mechanical gearbox. The advantages of these transmissions are in the automatic torque change depending on external resistances, the possibility of automating gear changes and facilitating control, filtering torsional vibrations and reducing the peak loads acting on the transmission units and the engine, and as a result, increasing reliability and durability. piston engine and transmissions.

The main disadvantage of these transmissions is the relatively low efficiency.

· Electromechanical transmissions have electric generators and traction motors and provide an automatic change in torque in accordance with the change in resistance to movement.

Technical characteristics of the T-330 tractor

Brakes - floating band type with hydraulic control, cardan drives of open type with needle bearings.

The main transmission is single-stage with bevel gears. This arrangement of the transmission was later used on almost all powerful industrial tractors.

The semi-rigid undercarriage consists of two track bogies swinging on the axle of the final drives. Track rollers and carrier rollers are attached to box-section crawler carts. The running equipment consists of two tracks, each with five support and two carrier rollers, and a tensioning mechanism. The torsion bar suspension of the road wheels improves ride comfort, reduces dynamic loads and ensures that all road wheels remain in contact with the ground. This makes full use of tractive effort and improves off-road capability.

Track rollers, carrier rollers and idler wheels - with one-time, "permanent" lubrication for life, with self-tightening DUOCONE seals. Track chain tensioning is simplified by a hydraulic tensioner installed in conjunction with the take-off mechanism. Track - with seal and lubrication of joints for life, with a split master link.

The working area is clearly visible from the double cab, sprung with rubber shock absorbers, with heat and sound insulation, fresh air ventilation. The elastic suspension seat is adjustable for load, height and tilt at the back. The ventilation unit is equipped with a hot air heater. Double-layer glazing protects windows from icing in winter. Conveniently located control levers and pedals, electro-hydraulic transmission control system reduces effort on the controls

Characteristics of T-330

Tractor type, caterpillar, industrial

Maximum tractive effort, kN (tf) 670 (68.2)

Engine brand, 8DVT ‑ 330A

Engine's type, turbocharged diesel

Engine power, kW (hp), 259 (352)

Speed \u200b\u200brange, km / h :

forward 0 - 16.4

back 0 - 13.7

Number of gears forward (backward), 3 (3)

Transmission, hydromechanical

Track suspension, elastic with balance bar

Specific pressure of caterpillars on the soil, kgf / cm2 , 0,57

Ground clearance, mm 570

Weight, kg 25000

Cab location , front

Project, year 1972

Produced, years. 1975-present

Appointment, industrial bulldozer ripper

Propulsion type, crawler

Single, mounted on rubber shock absorbers. Sound-absorbing upholstery, large, providing maximum visibility, glazing area with double-glazed windows, excluding icing of glass, sprung seat adjustable for individual weight and height of the operator, ventilation unit with a hot-air heater provide the operator with comfortable working conditions. Equipped with an independent diesel heater.

· Engine

Brand: 8DVT-ZZOA

Manufacturing plant: Volgograd motor plant

· Diesel type, 4-stroke, gas-turbine supercharged and air-cooled.

Operational power, h.p. (kW) 250

Rated frequency of rotation, rpm 1 700

Number of cylinders 8V

Cylinder diameter and piston stroke, mm 150x160

Specific fuel consumption, g / kWh 230

Oil consumption for waste from fuel consumption is less than 0.3%

Working volume, l 22.6

Weight, kg 2 600

· Hydraulic system

· Pumps Gear NSh ‑ 250, NSh ‑ 50UZ-L

Pump performance at rated engine speed, l / min 430 at 1,700 rpm

Set pressure of safety valves, kg / cm2: blade skew-160, blade and ripper-160

Blade lifting / lowering cylinders: 2

Diameter and piston stroke, mm 160x1250

Blade skew cylinder: 1

Diameter and piston stroke, mm 220x300

Ripper raise / lower cylinders: 2

- diameter and piston stroke, mm 220x560

Ripper cutting angle change hydraulic cylinders: 2

- diameter and piston stroke, mm 220x500

Refueling tanks

Fuel tank, l 670

· Lubrication system:

ICE, l 80

GTR, gearbox, KP, l 125

BR, l 2x45

Hydraulic system of attachments, l 370

Bulldozer equipment

Blade type Hemispherical (SU)

Blade width, mm 4 860

Blade height, mm 1 820

The volume of the drawing prism, m3 13

· Maximum lift of a blade, mm 1 530

The greatest depth of the dump, mm 650

· Angle of lateral skew of the blade in each direction, deg. 12

Weight, kg 7 030

Loosening equipment

Ripper type Parallelogram, adjustable angle

Loosening

Number of teeth 1 - tooth

Maximum lifting height, mm 950

The greatest deepening, mm 1 380

Loosening angle adjustment, deg ± 14

Burying force, kg 15 300

Dredging force, kg 56 400

Weight, kg 6 489

Movement speed, forward / backward, km / h:

I gear 3.5 / 2.9

II gear 6,4 / 5,4

III gear 13.0 / 10.8

Tractor weight, kg 41 800

Operating unit weight, kg 54 800

Specific ground pressure, kgf / cm2 1.127

· Traction class , tf rated thrust 25 t, maximum thrust 66 t

Full weight, t: 25 t

Occupational Safety and Health

- Before starting the diesel engine, lever C should be in the "H only after stopping" position, lever B and hydraulic distributor levers of the attachment hydraulic system should be in the "Neutral" position, and the parking brake should be applied.

- Before starting off, make sure that the path is clear and that there are no people between the tractor and agricultural implements, as well as in the area of \u200b\u200bthe frame pivot device. Warn about the start of movement with a signal.

- To work with trailers, semi-trailers and others vehicles only persons who know the rules of working with them are allowed.

- Trailed implements and trailers must have rigid couplings that do not allow them to run over the tractor.

- It is forbidden to ride on trailed implements not equipped for this, mounted machines and outside the tractor cab. More than two people, including the driver, are prohibited from entering the tractor cab.

- Keep the cab clean, the presence of foreign objects in the cab is unacceptable.

- There must be rubber mats on the cab floor.

- The tractor brakes must be in good condition. When braking with the service brake of a tractor moving on dry and hard ground at a speed of 8.3 m / s (30 km / h), the braking distance should be no more than 13 m; at a speed of 5.5 m / s (20 km / h) -6.5 m. Fully depressed brake pedal should not rest on the floor of the cab.

- When crossing dams, slopes and bridges, make sure you can drive through and use only reduced speeds.

- Move the tractor with mounted machines in the transport position with preliminary fixing of the mounted device by means of hydromechanical valves of hydraulic cylinders,

- Drive with mounted machines over ditches, bumps and other obstacles at a right angle at low speed, avoiding sharp jolts and large rolls of the tractor. - The overall size of the tractor with the installed nozzle on the exhaust pipe is 4.1 m. Care must be taken when crossing under power lines and low-sized driveways. If there is a sign limiting the driving height less than 4.1 m, the tractor must not drive with the exhaust pipe nozzle installed, in this case the nozzle must be removed.

- Choose a low speed when cornering.

- When driving downhill, do not roll forward. When driving on a straight coastline without a slope, set lever C to the "H only when driving" position.

- Drive the tractor to agricultural machines, implements or trailers at minimum speed with the drain pedal not fully depressed.

- In the event of a malfunction, the tractor must be stopped immediately until the malfunction is rectified.

- The permissible speed of the tractor on access roads and driveways is no more than 2.8 m / s (10 km / h), in production facilities - no more than 0.6 m / s (2 km / h).

- When loading (unloading) the trailer, the tractor must be properly braked, the parking brake must be applied.

- When aggregating with trailers or semi-trailers, attach their safety chains to the connecting links located on the lower link frames of the hitch.

- When working with the cables on the towing hooks, it is prohibited to stay in the radius zone of the cables.

- Cross the water crossing ford only after careful preparation and checking of the route. It is allowed to overcome a ford up to 1 m deep.

A first aid kit must be installed and secured in the tractor cab, completed in accordance with the instructions on its cover.

Conclusion

A bulldozer can perform almost any kind of work, work in a quarry, mine, in mining operations, as well as a bulldozer can work in an agricultural set, for felling or plowing land.

From all of the above, we learned the history of the production of tractors, the general description and use of tractors, we learned what they are. There was also a table with the largest tractor manufacturers, we also disassembled the tracked tractor T-330 (cheboksarets), its components and assemblies. Practical application and purpose.

Bibliography

1. Silaev G.V. Tractors and cars with the basics of technical mechanics: a textbook. For students of the specialty 2604.00 "Forestry". - M .: MGUL, 2001 .-- 347 p .: ill.

2. Melnikov D.I. M48 Tractors. M .: Kolos, 1981 .-- 336 p., Ill. - (Textbooks and textbooks for agricultural technical schools).

3. Gurevich A.M. Tractors and cars. - 3rd ed., Rev. and add. - M .: Kolos, 1983 .-- 336 p., Ill. - (Textbooks and textbooks for higher agricultural educational institutions).

4. Skidder TDT-55A and its modifications: T66 Study guide / IK. Emelyanov, E.M. Krasheninnikov, A.A. Boyda and others - M .: Lesn. prom-st, 1981. - 296 p., ill. In lane: 75 k. 24,000 copies.

5. Collection of normative documents for a labor protection specialist. - Administration of the NSO, State. Establishment "Novosibirsk Regional Center for Labor Protection", 2004. - 15

In 1975, the Chebaksar Plant of Industrial Tractors (now OJSC Promtraktor) began production of the heavy industrial tractor T 330. The unit was designed to offer consumers an alternative to imported expensive machines. The use and maintenance of rippers, pipe layers, and bulldozers created on the platforms CATERPILLER, KOMATSU, and other concerns led to significant foreign exchange costs.

The machine, assembled from domestic units and parts, turned out to be quite productive and efficient with a cost 2-3 times lower than that of Western competitors. Using the experience of its production and operation, the machine builders of "Promtraktor" have developed and still offer on the market the CHETRA T25 model - a modern heavy unit with bulldozer and loosening equipment.

Purpose and scope

Factory designation of the machine bulldozer T 330 P1-01. The heavy tractor is designed for cutting and moving soil layers from I to IV density categories, leveling the working surface of the working platform. T 330 is used in open pit mines, in land reclamation, for general construction and road works.

Purpose of the unit:

- development of the surface of the site in layers and movement of the removed soil mass, gravel, crushed stone and other materials within the working area;

- filling of excavations, pits, trenches, etc .;

- planning works and alignment of working sites according to design marks;

- formation of embankments - dams, dams, road bed, etc .;

- storage and mixing of nonmetallic building materials;

- excavation equipment for the construction of foundations;

- clearing areas and uprooting shrubs and small forests;

- snow removal work, anti-icing.

Specifications

| Power point | ||||

|---|---|---|---|---|

| Manufacturer Product designation |

JSC "VgMZ", Volgograd | |||

| Description | Diesel, 4-stroke, supercharged and air-cooled | |||

| Power parameter at 1700 crankshaft rpm, kW | 250 | |||

| Cylinders and their location | 8 x 4 per side in V-block | |||

| Fuel consumption, g / kW. hour | 230 | |||

| Total cylinder displacement, l | 22,6 | |||

| Weight parameter, kg | 2600 | |||

| Hydraulic units | ||||

| Pumping units | NSh-250, NSh-50U3-L | |||

| Performance index of the installation as a whole, dc 3 / min | 430 at 1700 rpm crankshaft | |||

| Cut-off pressure of protection valves kg / cm2 - | with a skew of the moldboard 160, for moldboard and ripper 160 |

|||

| Blade hydraulic cylinders, pcs | 2 | |||

| Ripper hydraulic cylinders, pcs | 2 | |||

| Hydraulic cylinders for changing the angle of cut for the ripper | 2 | |||

| Bulldozer equipment | ||||

| Moldboard device | hemispherical type | |||

| Blade blade width, m | 4,86 | |||

| Dump device height, m | 1,82 | |||

| Cut prism when moving, volume m 3 | 13 | |||

| Dumping device rise, mm | 1530 | |||

| Immersion in the soil of the dumping device, mm | 650 | |||

| Distortion of the moldboard device by side, deg. | 12 | |||

| Weight, t | 7,030 | |||

| Loosening equipment | ||||

| Ripper design - | parallelogram type, adjustable loosening angle | |||

| Number of working teeth | 1 | |||

| Rise to height, mm | 950 | |||

| Immersion in the ground, mm | 1380 | |||

| Ripper setting change, angular, hail | + 14 | |||

| Effort at penetration, kg when removing the ripper |

15300 | |||

| Weight parameter, t | 6,489 | |||

| General unit parameters | ||||

| Dimensions (L x W x H), m | 9.33 x 4.762 x 4.23 | |||

| Movement rate, forward / reverse, km / h I mode |

3,5 / 2,9 | |||

| II mode | 6,4 / 5,4 | |||

| III mode | 13,0 / 10,8 | |||

| Weight parameter of the tractor, t | 41,8 | |||

| Weight parameter of the unit with blade and ripper, t | 54,8 | |||

| The impact of caterpillars on the soil - specific, kgf / cm 2 | 1,127 | |||

Figure 2 Main executive body - dump

Figure 2 Main executive body - dump

Features of the device of the main components and assemblies

- The front positioning of the all-metal two-seater cab allowed the bulldozer operator to improve visual control of the blade.

- Hydromechanical transmission through: torque converter unit, gearbox, matching gearboxes, cardan shafts directs the diesel rotation energy to the drive sprockets caterpillar belts and a pumping unit for the hydraulic system.

- The torque converter continuously adjusts the motor torque to match the load on the dozer blade.

- Reversible gearbox, double-sided design. Forks the flow of power to the drive sprockets, allowing the machine to change direction and turn in place. Operated by hydraulic disc clutches, band stopping and reverse brakes.

- The final drives are made in two stages: the first gear stage with external engagement, the second planetary assembly with a braked carrier. The drive sprocket is bolted and replaceable.

- The semi-rigid travel system is assembled from two trolleys for tracks swinging on the side gear axle. The assemblies of the rollers, support and support wheels, of the direction wheels are filled with a one-time lubricant for the entire service life. Support rollers 14 supporting 4. A hydraulic device is installed to tension the chain.

- The track with a split link is assembled from 42 shoes with a link pitch of 250 mm. Shoe width 650 mm, contact with the soil over an area of \u200b\u200b4.86 m2.

In the control bodies of mechanisms and units of the T 330, mechanical drives are not used for the actuators, remote electrical and hydraulic systems with automation elements.

Heavy tractors made in Russia

The production of the T 330 bulldozer is discontinued. Specifications machines have been significantly improved in the series of Cheboksary CHETRA T units with model indexes 25, 35, 40:

- increased power and efficiency of power plants;

- pressure hydraulic equipment has become more efficient and reliable;

- increased traction loads and maneuverability;

- management has become easier and more convenient.

Due to the installation of aggregates and parts manufactured by foreign companies on the CHETRA tractors, the cost of purchasing and servicing bulldozers has increased.

TELL YOUR FRIENDS

In contact with