Bulldozers of Russian production in comparison with foreign models have a lower cost. The advantage of domestic special equipment is not only the simplicity of the design, which allows you to repair the bulldozer at home, but also find spare parts for our machines much easier. The USSR, one of the first countries, began the production of heavy bulldozers. Continuing many years of experience, models of the Chelyabinsk Tractor Plant are still popular in Russia and the CIS countries.

Bulldozers of Russian manufacturers are domestic construction units that perform many functions. The main functions are moving large amounts of land or snow over short distances, mining natural resources in quarries, road construction and many other works. We invite you to familiarize yourself with the most popular Russian bulldozers, which are the models of ChTZ and Volgograd TZ.

The Russian bulldozer T-130 was produced by the Chelyabinsk Tractor Plant in the period from 1969 to 1988. The 130th model has a diesel four-stroke, four-cylinder turbocharged diesel engine with an output of 140 hp. And its structural weight is 12 720 kg. There is an opportunity to complete attachments: traction winches, dozer blade, etc., depending on the wishes of the client. This model is the basis for many types of special equipment.

Russian bulldozer The T-170 with a straight blade is also the creation of ChTZ. This model is highly maintainable and able to operate under the most incredible climatic conditions. On the domestic market, only foreign machines are analogues, but the price of the T-170 is much lower. The straight blade allows you to tackle tasks from overburden to hardened clay mining and other similar tasks, enabling grading work.

The Russian-made bulldozer DT-75 was created by the Volgograd plant. In 2008, VTZ celebrated the 45th anniversary of the start of production of the most popular tractor in the Soviet Union. The 75 has earned a good reputation for its combination of high performance and low cost in its class. A four-stroke, four-cylinder SMD-14 diesel engine was installed on this model. liquid cooling with a capacity of 75 l / s. For 46 years, more than 274,000 units of such special equipment have been produced, which says a lot.

Rent of Russian bulldozers

Russian-made bulldozer for rent - this is the best way take advantage of the high quality of special equipment of the Soviet manufacturer. We give you the opportunity to order one or even several models you like for any period. All our machines are kept in perfect condition and are regularly inspected. Time-tested domestic equipment will be indispensable where other foreign special equipment cannot work. It is operated absolutely in all weather and climatic conditions. Using our bulldozers is as convenient and simple as possible for any trained Russian operator-driver.

Renting a Russian bulldozer is a choice in favor of power and reliability in any work. Due to the wide area of \u200b\u200bthe tracks, which distribute the weight of the machine evenly, there is no need to be afraid that during operation the equipment will wither in a quagmire or liquid soil composition. The lack of roads for Russian bulldozers is irrelevant, you can comfortably and conveniently work on the roughest terrains. We offer special equipment of various weight categories for a wide variety of purposes.

Rent Russian bulldozers - it's simple and convenient. You can order any offered heavy equipment in a way convenient for you. Leave a request on our website and we will contact you ourselves. Or you can call our specialist and find out all the detailed information about the services and technology provided. We guarantee high-quality work of any unit of special equipment, your construction will not drag on with us for a long time. We will promptly resolve any of your problems related to the lack of special equipment.

No construction site can do without equipment such as a bulldozer. The trend of intensive growth in the construction of residential buildings, offices, as well as road construction, has led, accordingly, to an increased demand for this product. The country's government is committed to a policy of gradually replacing exports of construction equipment with domestically produced machinery. How does this threaten the construction industry? We propose to identify the main pros and cons of using bulldozers of domestic and foreign manufacturers.

An obvious plus from the use of domestically produced bulldozers is that in the event of a breakdown, it will be much easier to purchase parts for it than for a bulldozer from foreign manufacturers. Of course, the cost of such spare parts and components manufactured in Russia will be an order of magnitude lower than the imported analogue.

The main advantage of bulldozers imported production is their progressiveness and compliance with international quality standards. Builders preferring bulldozers of foreign manufacturers note, first of all, their compliance with market requirements. Dressta Co. is a good example. Ltd. The bulldozers of this company are expanding their assortment, studying the demand. Today their production includes crawler tractors of various traction classes, bulldozers with wide crawler tracks, which are excellent for work in soft and swampy ground, as well as bulldozers with extended crawler tracks.

Another supplier widely known among builders in our country is the Japanese concern Komatsu. This manufacturer also offers a wide range of bulldozers, both standard and optional. For example, a Komatsu bulldozer ideal for soft ground is equipped with wider tracks. In this way, imported manufacturers focus on a wide selection of machines for different needs: different bulldozers are engaged in weak, loose, swampy areas of soil. However, as practice shows, most construction companies in our country cannot afford to use several different bulldozers. Preference is given to universal machines that are suitable for any kind of soil.

Another advantage of foreign-made bulldozers is their design compliance with global trends. So, their appearance is always attractive, original. One gets the impression of lightness and grace even of such a voluminous and heavy structure as the body of a bulldozer. The original design solution was embodied not only in the exterior of the car, but also in the interior of the cab. Its content fully meets the needs of the worker. The configuration and equipment of the cab represent a comfortable and safe environment that meets the highest international requirements.

Finally, it is not surprising that foreign manufacturers pay so much attention to the environmental friendliness of their products. Engines used in bulldozers are distinguished by low emission and low noise levels. This helps to protect the environment.

Summarize. The current situation in the country has led to the fact that today one basic requirement is imposed on bulldozers: they must help to reduce the time of construction work. This can be achieved in two ways: either use more machines, or use machines that are more productive. As mentioned above, overseas manufacturers benefit from productivity issues. However, the low cost with a decent quality of domestic bulldozers allows you to use several machines at the same time. This factor, combined with the low cost of warranty and post-warranty service, makes domestic bulldozers more attractive for our specialists. When it comes to design and sustainability, these factors fade into the background, yielding to performance.

Publication date: 2011-08-06 15:35:08

Source: http://www.stroi-tehnika.ru/content/articles/index.php?news\u003d2042 All articles of the section " Bulldozers »

Most read articles in the "Bulldozers" section:

|

12.10.2007 23:50

Bulldozers from different manufacturers - overview Bulldozers always appear at construction and industrial sites, where they are involved in carrying out relief work on the ground. Bulldozers are among the first to appear on almost all construction sites for the construction of residential buildings and the planning of adjacent streets, as well as for the construction of office buildings and shopping complexes. Section: "Bulldozers" |

||

|

12.10.2007 23:50

Caterpillar D6K Crawler Bulldozer The D6K is the first in a new line of Caterpillar tracked dozers to feature the latest hydrostatic transmission and SystemOne undercarriage. This provided the bulldozer with high performance ... Section: "Bulldozers" |

||

V.D.Kovrigin, Leading Researcher, FSUE NATI

Crawler bulldozers are one of the main types of earthmoving equipment, which is widely used in the mining, oil and gas and road construction industries.

Large-scale development of these complexes, the growth of reclamation work and the development of the raw material base of Siberia and the Far East in 1970-1990. demanded the use of bulldozer equipment of large unit power.

The bulldozer successfully combines the capabilities of an excavating and transport machine and is used in open pit mining of alluvial deposits, coal and ore quarries.

The greatest efficiency of bulldozing operations in open-cast mining of low-thickness seam deposits and especially in selective mining of minerals from thin seams.

Bulldozers in northeastern Russia operate under extreme conditions in the development of alluvial deposits from + 30 ° C to -50 ° C. So, in the warm season, bulldozers are used in layer-by-layer peat mining and mining operations to supply gold-bearing sand to the washing device. In winter, at temperatures down to -50 ° C, bulldozers are used for stripping operations when excavating frozen rocks destroyed by drilling and blasting.

Until 1975, the only model of a powerful domestic bulldozer for industrial use based on the DET-250 tractor with a power of 220 kW (300 hp) was in operation. The first samples of foreign-made bulldozers were purchased in the period 1969-1974.

During this period of time, when domestic mining enterprises were in need of powerful bulldozers, Caterpillar, Komatsu, Fiat Allis and Dresser were active in the market for such machines. In the practice of such activities, the principle of preliminary operational tests of bulldozers in real production conditions was applied. This test was passed by Caterpillar D10, D9L bulldozers, Komatsu D85, D155, D355, D375 and D475 bulldozers, Dresser TD 40C bulldozers, Fiat Allis FD 50 and FD 40 bulldozers.

At present, Caterpillar, Komatsu, Dressta continue to maintain strong positions in the Russian bulldozer market from foreign companies.

To fully meet the need for powerful domestic crawler bulldozers in 1972, the construction of the Cheboksary industrial tractor plant began, which in 1975 began the production of the T-330 tractor with a capacity of 243 kW.

Until the beginning of the 90s, the production of bulldozers and rippers was carried out by enterprises of two departments. Tractors, as basic machines of bulldozer-loosening units, were produced at the factories of the Ministry of Tractor Agricultural Machinery and were supplied to the Ministry of Construction Industry for the installation of attachments (blade, ripper). By the mid-1990s, this system had changed. Currently, factories that produce industrial tractors themselves manufacture and install attachments on them.

The following circumstances contributed to the successful promotion of foreign-made bulldozers on the Russian market. Caterpillar, Komatsu, partly Dressta and subsequently Liebherr produce a wide range of bulldozers, excavators, pipelayers, mining dump trucks and wheel loaders.

On the basis of this technique, the firms offered mining enterprises a technologically linked complex of machines with service and supply of spare parts.

In addition, the companies carefully studied the operating conditions of earthmoving equipment, which made it possible to develop a number of measures aimed at maintaining a high level of machine reliability in difficult conditions work.

The equipment was equipped with a number of additional systems aimed at improving engine start-up in winter and creating comfortable working conditions for operators. Pre-heating devices for engine systems, transmission oils and hydraulic systems, cab heating were introduced, i.e. the firms offered the consumer special machines in the performance of –40 ° С and –50 ° С.

At present, the market of Russian-made bulldozers for the mining industries of Russia is represented by domestic models produced by OJSC Promtractor and OJSC Chelyabinsk Tractor Plant - Uraltrak.

Bulldozers of OJSC "Promtractor"

The widest range of bulldozers is offered by Promtraktor, whose standard size range consists of 6 basic models in the power range of 123–550 kW (Table 1). The standard-size range is created according to a single standard design-layout scheme, which is based on the principles of unification, typification and modularity of structures.

The base tractors are equipped with engines of domestic production of the Yaroslavl Motor-Building Association and the Cummins company (USA), use hydromechanical transmissions with torque converters, planetary reversible gearboxes with load shifting, providing 3 forward and reverse gears, with a reverse speed of 25-30 % higher than the front ones (Table 1).

Currently, there are three types of torque converters with active diameters of 430, 480 and 530 mm, three types of gearboxes for powers from 145 to 220 kW, from 250 to 390 kW and over 550 kW. The main gears are made in three similar power ranges, have a single-stage matching reducer and a bevel gear pair with a circular equal-falling tooth.

Steering and braking mechanisms are multi-plate clutches operating in oil. Final drives (reducers) - two-stage. The first stage is a spur gear, the second is a planetary type.

The running system is made with a semi-rigid suspension, both with diagonal and non-diagonal options. The swing axis of the tracked bogies is separated into a separate unit, isolated from the axle of the final drive.

Tracks are greased pivot, track and carrier rollers are Duo-cone seals with one-time lubrication for life.

Single cabins are installed on rubber shock absorbers, have a large glass area, good visibility, double-glazed windows prevent the glass from icing.

The cab has sprung seats that adjust to the individual operator's weight and height. The ventilation unit with an air heater (heater) provides the required temperature regime in the cabin. On request, the cab can be equipped with air conditioning. The cab meets international safety requirements and is equipped with a ROPS system (operator protection in the event of a rollover of the machine).

The hydraulic attachment control system provides all the functions necessary for bulldozers and rippers. At the drain in the hydraulic system, full-flow filter elements with a cleaning fineness of 25 microns are used.

Motor units have either transmission and engine oil heat exchangers built into the engines, or the transmission heat exchanger is integrated into a single unit with a liquid engine cooling radiator. The air cleaning system is two-stage, the first stage consists of a cyclone, and the second one consists of paper filter elements. Tractors are equipped with pre-heaters to facilitate engine starting in cold season.

Thus, when creating a new family of crawler bulldozers, the following basic principles were implemented:

Use of design solutions, proven by long-term operation of similar machines of domestic and foreign production;

Identification of technical solutions that reduce the complexity of work in the manufacture and repair of machines;

The use of a modular layout of components and assemblies;

Constructive similarity of machines, which allows typing the issues of production technology, operation and repair;

Achieving the maximum level of unification, both between the standard sizes of machines of similar classes, and when creating specialized modifications based on them;

Providing the possibility of using various types of engines of domestic and foreign production.

All models of bulldozers of JSC Promtractor have passed acceptance tests at the mining enterprises of the Far East, Siberia, the Urals and the European North of Russia. Since 2001, the production of tractors of the old T-330 and T-500 models has been discontinued.

Bulldozers of JSC "Chelyabinsk Tractor Plant"

For the enterprises of the mining industry and the fuel and energy complex, this oldest tractor plant in Russia produces crawler bulldozers of three standard sizes of five basic models (Table 2).

In the period 2001-2002. The plant carried out a set of works on modernization of the bulldozers produced, aimed mainly at increasing the level of reliability and resource, as well as the comfort of the operator's working conditions. Major improvements include a 25% increase in engine torque reserve, the use of an improved engine cooling system and a rigid beam suspension system, swing mechanisms and oil brakes. The cab is equipped with a new heating and ventilation system and a rollover safety system (ROPS).

The designers of the plant have developed a model of a bulldozer with a six-cylinder Cummins diesel engine model M11-C with a power of 140 kW and a chassis system using Berco components. New elements in the bulldozer are: sector-type design of drive wheel rims, all-welded idlers, support and support rollers with a one-time refueling designed for full service life, tracks with a split closing link.

The DET-250M2B1R1 model occupies a special place in the series of Uraltrak tracked bulldozers, which differs from similar machines by the use of an electromechanical transmission, which provides automatic regulation of traction forces and operating speed depending on external loads over the entire operating range.

The features of this bulldozer should also include the use of two-stage planetary slewing mechanisms and an elastic torsion bar suspension of each support roller of the undercarriage system, which makes it possible to realize increased speeds in transport modes (up to 16 km / h).

Bulldozers of foreign firms

The most complete structural series of the basic models of foreign-made crawler bulldozers-rippers have been created and produced by four companies. The structure of such standard size series of foreign manufacturers and JSC "Promtraktor" is presented in table. 3. As can be seen from the table. 3, Leading companies Komatsu and Caterpillar have the most complete dozer lines, covering a power range from 29-52 kW to 634-784 kW, and evenly distributed across the number of models between light, medium and heavy categories.

The standard-size series of Dressta and Liebherr companies are shifted to the zone of bulldozers of the light and medium category, and the number of Promtraktor OJSC is represented by the medium and heavy category. The light category of bulldozers in the domestic market is produced by OJSC "Chelyabinsk Tractor Plant - Uraltrak" and OJSC "Volgograd Tractor Plant".

In Russia, for the needs of the mining industry and the branches of the fuel and energy complex, mainly bulldozers of medium and heavy categories are used.

The first deliveries of foreign bulldozers to the domestic market began with the Caterpillar D 9G model in 1969. In the future, this company continued to supply machines of this class, and later a more powerful bulldozer D 10. Later, the Japanese company Komatsu supplied bulldozers of the D 65 model (mainly for the construction of forest roads in the Far East) and models D 155, D 355 and D 455 for mining enterprises of Yakutia, Magadan region and Chukotka. Deliveries of bulldozers of medium and heavy categories were carried out by Dresser and Fiat Allis. The largest batches of bulldozers (over 3500 units) were purchased in the period 1971-1980.

In subsequent years, up to 1985, this trend continued. Increasing production volumes and expanding the range of bulldozers at ChZPT "Promtractor" and the ongoing economic reforms in the country contributed to a decrease in the volume of purchases of bulldozers abroad. Thus, the average annual purchase of bulldozers in non-CIS countries for the period 1996-2001 averaged 160 pcs.

Characteristics of the bulldozer fleet in Russia

At present, the fleet of foreign bulldozers in Russia is represented by machines of the following companies: Caterpillar, Komatsu, Dressta, Liebherr and Fiat-Hitachi. From the latest models of these companies, the following bulldozer models were delivered to the market of bulldozers for the mining industry and the fuel and energy complex of Russia: D 8R, D 9R, D 10R from Caterpillar; D 155A-3, D 355A-3, D 275A-2, D 375A-Z, D 475A-3 from Komatsu; TD 25G (H) and TD 40C from Dressta; PR 752 and PR 751M from Liebherr. Specifications these machines are shown in tables 4, 5 and 6.

Constructive basic solutions of domestic and foreign bulldozers meet modern trends in the development of this type of equipment. The features of foreign bulldozers include:

Caterpillar bulldozer applications with engines automatic system regulation of fuel injection depending on the load, power flow divider, which allows 25% of the engine power to be transferred mechanically, and 75% of the power through the torque converter;

The use of a torque converter lock-up mechanism on powerful Komatsu bulldozers;

Equipping some models of bulldozers with stepless swing mechanisms;

The use of only hydrostatic transmissions on Liebherr bulldozers, which significantly simplifies the structure of the transmission itself and provides maximum tractive effort per unit of tractor weight;

The use on Caterpillar bulldozers of a triangular crawler track with highly raised drive wheels, as well as an elastic suspension of the undercarriage system, which allows the drive wheels to be removed from their direct contact with the ground and helps to reduce the intensity of their abrasive wear and dynamic impact. At the same time, the use of an elastic suspension ensures the maintenance of constant contact of the tracks with the ground, while maintaining high traction and coupling properties. In this case, the design of the suspension and the frames of the tracked bogies is significantly complicated. The elastic method of suspension of the undercarriage system is used for a similar purpose on the Komatsu bulldozers, but at the same time the company retained the traditional elliptical caterpillar track;

The use of all-metal single-seat, mostly hexagonal cabins with a large area of \u200b\u200bglass, providing an adequate level of visibility to the front, rear and side. The cabins are equipped with anatomically adjustable swivel and sprung seats (depending on the height and weight of the operator), as well as modern control systems, mainly of the joystick type. Significant progress has been made in equipping bulldozers with systems for automatic control over machine parameters and warning information for the operator about possible emergencies, as well as systems for maintaining a microclimate;

The use of improved designs in the mechanisms for connecting the bulldozer equipment with the base tractor, allowing to improve the kinematics of the blade movement and bring the blade closer to the tractor. This made it possible to somewhat reduce the overall length of the bulldozer and increase the depth and pressure on the blade.

The comparative tests of the bulldozers of OJSC Promtraktor and OJSC Chelyabinsk Tractor Plant - Uraltrak with their foreign counterparts showed that the bulldozers are practically equivalent in technical performance. However, the experience of operating bulldozers in real production conditions shows that in terms of annual operating time (in engine hours) and average annual operational productivity, foreign bulldozers surpass domestic ones (analogs in power, weight, blade type) by an average of 15% and 30-35%, respectively. ... This is due to a higher level of reliability and, thus, a higher rate of technical utilization of machines.

The main factors determining the development of the bulldozer market

As for the further development of the bulldozer market, consumer demand will be determined by the level of implementation of the adopted federal and regional programs for the development of specific industries for the short-term (2002-2005) and medium-term (2006-2010) prospects.

In road construction, it is envisaged to build and reconstruct 61 thousand km of territorial highways by 2010. The priority will be given to objects and directions that are of the greatest importance for the development of both individual regions and the country as a whole. In particular, this is the Omsk - Novosibirsk - Kemerovo - Krasnoyarsk - Irkutsk - Ulan-Ude - Chita - Khabarovsk - Vladivostok highway. Measures for the repair and maintenance of roads provide for an annual increase in the volume of repair work by 4-6% in the period 2002-2005. with a subsequent growth by 1.6 times in the period 2006–2010.

In the oil production complex until 2005, it is planned to develop about 100 new oil and oil and gas fields in Western Siberia, the Perm region, the Komi Republic, the Nenets Autonomous Okrug, the Volga region, Eastern Siberia and the Sakhalin region. In the period 2002-2005. it is planned to build and reconstruct more than 2,500 km of oil pipelines and more than 2,600 km of oil product pipelines, and in the period 2006–2010, respectively, about 3,000 km of such pipelines.

In the gas production industry, the modernization and reconstruction of 23,000 km and the construction of 22,000 km of trunk gas pipelines are envisaged, and the increase in the network of distribution gas pipelines should be 75-80 thousand km, 75% of which is in the countryside.

IN coal industry for the period 2002-2005 it is planned to reconstruct existing mines and build 10 new mines and 47 open-pit mines. The main volume of commissioning of new capacities falls on the Kuznetsk and Kansk-Achinsk basins and fields in the Far East. For the period 2006–2010. 8 new mines and 22 open-pit mines are to be commissioned. Fulfillment of these tasks will require an increase in the volume of stripping works, which may amount to over the period 2002-2005. - 170-175 million m3, and for the period 2006-2010. - 100-110 million m3.

In the electric power industry, it is planned to build medium-sized hydroelectric power plants on the Zeya (Amur Region) and Ugur (South Yakutia) rivers, as well as the Lower Angara (Krasnoyarsk Territory).

In the development of railway transport, in addition to the reconstruction of 5,840 km of roads for high-speed train traffic and the electrification of 6,900 km of railways, it is planned to build and lay about 1,500 km of new roads, including to the Chineyskoye ore and Elga coal deposits.

In the field of aviation transport, it is planned to build 33 runways and complete the construction of new aviation complexes in the cities of Omsk and Syktyvkar.

The projected increase in demand and growth in demand for bulldozers with an average annual rate of 4–6%, i. E. the total need for bulldozers with a capacity of more than 300 hp in 2003-2006 will average 700-750 pcs.

Thus, at present, Russian factories produce the necessary range of bulldozers, both in terms of power, standard sizes, and traction classes... However, in modern market conditions, domestic bulldozer manufacturers need to take care of reaching the world level of operational reliability and reliability of equipment, as well as urgently take measures aimed at significantly reducing the operating costs of the consumer.

Historically, the production of bulldozers in Russia has experienced ups and downs twice. The first take-off dates back to 2000, when production volumes exceeded 3000 units, while usually the production of bulldozers did not exceed 1600-1800 cars per year. The second peak occurred during the 2007-2008 construction boom. Then came the crisis, the production of bulldozers fell sharply by 4.5 times, and then for three years it was restored to its average level.

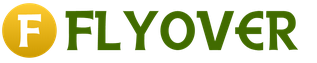

Figure: 1. Production of bulldozers in Russia, pcs.

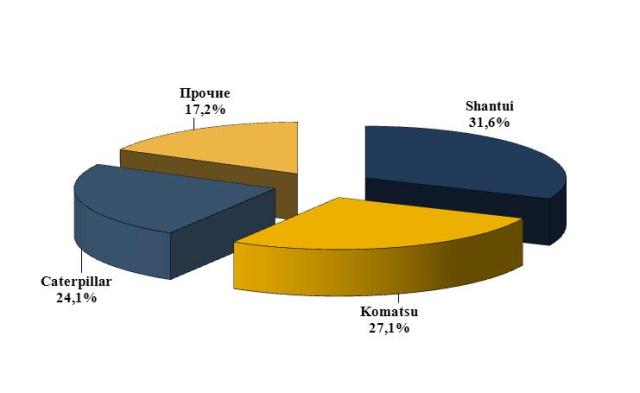

According to Rosstat, the main manufacturer of bulldozers in the Russian Federation is the Chelyabinsk Tractor Plant Uraltrak, which accounted for more than 64% of the total output last year. The second place belongs to the Cheboksary Promtractor with 34.5% of the total volume. According to the consulting company ASM-holding, the Volgograd Tractor Plant, which produces tracked tractors and bulldozers based on them, is also among the manufacturers of bulldozers. Taking into account VgTZ, Uraltrak accounts for 49.7% of bulldozers produced last year, Promtraktor - 26.8%, and VgTZ - 22.6%.

The dynamics of bulldozer production last year clearly shows that the crisis is over. Monthly volumes last year did not fall below 129 vehicles, while in 2009-2010 they sometimes dropped to 14-15 bulldozers per month.

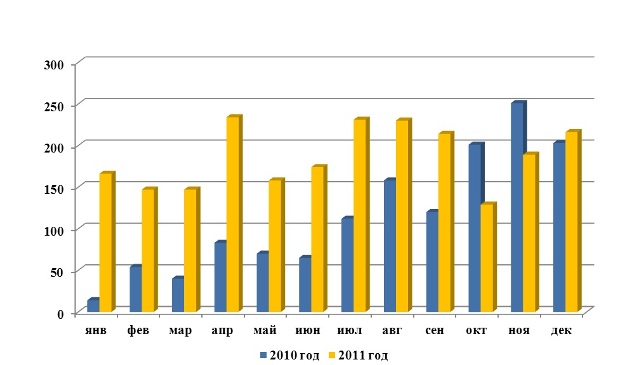

The import of bulldozers in the post-crisis years exceeds domestic production. In 2011 the share imported equipment in the domestic market of the Russian Federation increased by 3.1% from 58.5 to 61.6%. In total, 3189 cars were imported to Russia last year, which is almost 2 times more than a year earlier.

For the second year in a row, the Chinese SHANTUI bulldozers, which are essentially a high-quality copy of Japanese Komatsu, hold the first place in terms of import volumes. The lineup also repeats one to one Komatsu. But the price of Chinese cars is 2-3 times lower than that of the Japanese original. Actually, thanks to its low price, before the crisis, Shantui steadily increased its share in imports by 2-3% per year, and in 2010 bypassed all rivals in a bend, occupying more than a third of the Russian market of foreign-made bulldozers. At the end of last year, Shantui's share dropped to 31.6%, but Chinese equipment continues to be the absolute leader on the Russian market, outstripping even the Chelyabinsk Uraltrak in terms of the number of cars.

KOMATSU is firmly in second place - in the recent past, the market leader, which accounted for a third of the import deliveries of bulldozers to our country. Alas, the Japanese company has personally raised a competitor in the face of Shantuithat knocked her off the pedestal (the Shantui plant was built in 1980 with the assistance of Komatsu). As mentioned above, the prices for Japanese equipment are 2-3 times higher than for Chinese, but real Japanese quality is expensive. Anyway Komatsu it doesn't give up so easily and by the end of 2011 managed to increase its share in the Russian market by 3.5% compared to the previous one.

The American caterpillar, nicknamed CATERPILLAR, finished the top three in imports in 2011 with a score of 24.05%. Despite the fact that Caterpillar has never been the first in terms of the number of cars supplied to Russia, the American consistently leads the rating in terms of supply in monetary terms. Firstly, because it is significantly more expensive than a similar Japanese and even more so a Chinese, and secondly, because the share of new bulldozers in the volume of imports has always been higher than that of Komatsu.

In the past year Caterpillar not only increased its presence on the Russian market by 3.9%, but also reduced the share of used machinery in the volume of imports by 22%, bringing it to 86.3%. By comparison, Komatsu had only 60% new machines last year.

Figure: 4. Import of bulldozers in 2011 and shares of major manufacturers,%

Bulldozers are mainly exported to the CIS countries. At the end of last year, 250 vehicles were sold abroad, which is 26 bulldozers more than in 2010. More than 93% of export falls on Russian-made cars. The rest are used imported bulldozers, one of which is already produced in 1986. That is the same age as Perestroika.

The leader in terms of supply volume is, naturally, the Chelyabinsk Uraltrak, which accounts for over 70% of all Russian exports. It is noteworthy that a year earlier the share of Uraltrak was only 30%, and the leader in terms of export volume was the Cheboksary Promtraktor.

Figure: 5. Russian bulldozer market in 2011 and shares of major manufacturers,%

The apparent internal consumption of bulldozers at the end of last year amounted to 5174 units, which is 87% more than a year earlier. Considering the fact that in 2008 the apparent domestic consumption was 5,431 vehicles (5% more than in 2011), we can assume that the Russian bulldozer market has practically recovered.

The universal equipment from which almost every construction site begins is a bulldozer. The appearance of these powerful machines has remained unchanged for many years - a caterpillar tractor, in front of which a tool for work is attached - a metal blade. The bulldozer is unpretentious in maintenance ‚has a high cross-country ability and maneuverability.

Due to the peculiarities of production (modular replaceable units), bulldozers have a high degree of maintainability. On construction sites, you can also find pneumatic bulldozers, which work on cleaning work and on light soils.

The main function of a bulldozer is to move large volumes of soil over short distances. Bulldozers are used in the construction of dams and dams, grading embankments, dirt roads, soil removal, backfilling of trenches, leveling of soil surfaces. Due to the versatility of the machines, they are also used in the preparation of the road right-of-way - complete clearing of the strip from trees, uprooting stumps.

The machines can be equipped with various types of dozer blades: straight, spherical and hemispherical (universal and semi-universal in international terminology), rotary (i.e., turning in plan), with a lateral skew (when one blade angle is raised above the other) and a variable cutting angle ( blade angle in side view).

Russian builders are familiar with various models of bulldozers from various manufacturers of this equipment, both domestic and foreign.

Within the framework of international cooperation in the 70s, Soviet factories widely cooperated with Polish machine builders, including the plant in the city of Stalowa Wola, which is well-known in Russia, and the construction equipment of the Stalowa Wola brand has proven itself well on our construction sites.

Since the beginning of the 70s, the machine-building plant Huta Stalowa Wola through cooperation with the world's leading manufacturers construction machinesIncluding with the International Harvester, in a short time he completely rebuilt the production in accordance with the requirements of the market and achieved recognition of his products. As a result of the partnership between the American company Komatsu Dresser Company and the Polish concern Huta Stalowa Wola, a joint trade and marketing firm Dressta Co. was founded. Ltd. Is a well-known name of a foreign supplier among Russian builders.

Bulldozers supplied by Dressta are available in several modifications: caterpillar tractors of various traction classes, machines with a widened caterpillar track (suitable for work on soft and swampy soils), machines with an extended track length. Dressta bulldozers are equipped with engines, depending on the model Cummins or Komatsu... They are equipped with a modular drive system, that is, any of the units, if necessary, can be removed and replaced without dismantling the adjacent units and assemblies. Splined joints between transmission units do not require adjustment and precise installation relative to each other.

The lightest bulldozers in the Dressta range are equipped with a six-stage blade, while other sizes can be equipped with straight, pivoting, hemispherical and spherical blades. Additionally, bulldozers can be equipped with loosening equipment, and the number of loosening teeth ranges from one for the most powerful machines to five for light machines. The maximum loosening depth is 1.7 m.

Dressta bulldozer cabins resemble truncated pyramids with 4 or 6 sides. The interior of the cabs, as well as their standard and additional equipment, fully comply with international requirements in terms of operator comfort and safety.

Russian builders are also well acquainted with the equipment of the world's leading manufacturer, the Japanese concern Komatsu. Japanese machine builders have been cooperating with domestic construction organizations for a long time - the first samples of Komatsu equipment for the development of the Far North were delivered to the USSR in the 60s.

Komatsu crawler dozers are available as standard equipment and in various options. The bulldozer can be equipped with widened tracks and is designed for soft soils; can be produced with an extended base. In addition, the machine can be equipped with a hydrostatic motion control system. The range of non-standard equipment offers rubber caterpillar beltsSilent machine running, gentle on the floor and maintenance-free. Rubber tracks can be of two types: standard for normal ground conditions and widened for working in wetlands.

The appearance of the latest Komatsu crawler bulldozers is quite attractive and unusual ‚gives the impression of lightness and grace.

Komatsu equips the machines with diesels of its own production, specially designed for earth moving machines. These medium-speed direct injection engines are characterized by good performance ‚high torque‚ fuel efficiency and low emission toxicity.

Komatsu bulldozer cabins fully comply with the requirements of international and national certification bodies for operator comfort and safety.

The largest line of manufactured equipment belongs to the Caterpillar brand. These machines, enjoying well-deserved fame, are well known to domestic builders for more than a dozen years.

The company equips its bulldozers with diesel engines of its own production, designed taking into account the peculiarities of the work of earth-moving machines. The most important characteristics of engines are high power and increased torque reserve.

Caterpillar bulldozers are standard on heavy dozer and grading jobs. The company also supplies several specialized versions. Bulldozers can be produced with increased power and an extended base, which provides increased operating speeds, more even distribution of the support load, improved layout and good directional stability. Machines are produced with a larger track and widened tracks, allowing you to work effectively on loose or excessively wet soils.

The field of application of wheeled dozers in general and Caterpillar in particular differs from the field of application of tracked vehicles. Wheeled bulldozers used on lighter soils and stripping jobs. Lighter jobs correspond to less traction, higher speeds and the vulnerability of rubber tires. They have many common components and assemblies with pneumatic wheel loaders, including the articulated frame.

On the front of it, dozer equipment is mounted, on the back - the cab, engine compartment and transmission. Pneumatic bulldozers are powered by Caterpillar engines, which are designed to be modular overhaul‚And repair with the replacement of individual parts. The front axles are rigidly connected to the front part of the frame, the rear axles can swing in the transverse plane relative to the frame by ± 12-15 °. The cabins are equipped with safety structures, air conditioners, air filters, an anatomically adjustable seat and an adjustable steering column.

The German concern Liebherr produces a more modest range of tracked bulldozers. True, each of the models can be supplied in 7-9 modifications (different blades, tracks, tracks and rippers), so the actual number of models is much larger.

The Liebherr concern produces crawler dozers of various traction classes. The machines can be produced with an extended caterpillar track and equipped with wide tracks for work on soft and swampy soils.

Liebherr is the developer of the electronic hydraulic system Litronic‚Combining the intellectual abilities of a modern computer and the capabilities of the latest hydraulic mechanisms. On tracked bulldozers of the company, the Litronic system is responsible for the operation of a hydromechanical travel transmission with a hydrostatic drive. Serious attention is paid to maintenance. The Litronic system provides automatic monitoring of the condition of the hydraulic system units and, if necessary, fault diagnosis. The main points of servicing the bulldozer and diagnostics of its units are grouped and located in an easily accessible place.

Liebherr bulldozers are equipped with diesel engines of their own production, designed specifically for construction machines. These medium-speed long-stroke direct injection engines are economical, low-emission and quiet.

Bulldozer equipment is equipped with one of the following types of dumps: straight, hemispherical, spherical or rotary with a variable angle of inclination.

Fiat-Hitachi is another big name in the road and construction machinery market. Bulldozers are poorly represented in the company's product range and are not very often purchased by Russian construction contractors.

Bulldozers are equipped with hemispherical, spherical and swivel blades of various capacities and single or three-shank rippers with a parallelogram suspension, which keeps the ripping angle constant at any depth. Diesel engines are installed on the machines Fiat with direct injection ‚increased piston stroke and reduced crankshaft speed. According to the company, machines with these motors can effectively operate at altitudes up to 2,500 m without special equipment. The operator's cabin meets the standards of international certification organizations in terms of comfort and safety.

The standard equipment of the cab includes: an adjustable seat with seat belts, an electronic digital monitor with light indication of emergency situations, an air cleaner and a fan, structures ROPS / FOPS and heating. Tilting the cab with a special hydraulic lift facilitates access to the transmission units during maintenance. The intertrack joints of the track chains, the bearings of the rollers and sprockets are filled with long-term grease and are sealed. The tracks are tensioned by the front driven sprockets ("sloths") under the action of springs and hydraulic tension cylinders. The rollers and sprockets are equipped with special protection against possible damage, and special guides prevent the tracks from jumping off when maneuvering.

Traditional ideas about bulldozers can be fully attributed to the appearance of Fiat-Hitachi cars. The company's designers have created a modern design, giving the cockpit the appearance of a multifaceted truncated pyramid and replacing the smooth outline of the body with pronounced edges at the joints of the flat facing elements of the casing and hoods.

Case bulldozers are increasingly seen on Russian construction sites. The Case lineup includes relatively small machines: the operating weight of the heaviest of them is just over 12 tons. Bulldozers are equipped with engines of their own production. The undercarriage uses tracks with closed and permanently lubricated joints, as well as closed track rollers, drive rollers and drum sloths with "permanent lubrication". Scope of delivery may include wider tracks and wider tracks with increased ground contact to improve machine stability, reduce sinking, improve side slope and finish leveling performance.

Case strengths are the reinforced electrical components used in bulldozers. The use of these elements allows the machine to be started and operated in extreme weather conditions.

Traditionally, a lot of attention has been paid to the maintenance of machines, with quick-change spin-on filters, easy-opening access door and grouped service points. Ease of operation and high operator comfort are standard on Case dozers.

The oldest tractor plant in Russia is the Chelyabinsk Tractor Plant (ChTZ). ChTZ began its history as a Komsomol construction site in the 1930s, and already in 1938 the S-65 tractor was awarded the highest Grand Prix award at the World Exhibition in Paris. In 1984, ChTZ produced its millionth tractor from the assembly line.

ChTZ bulldozers are an integral part of the Russian construction landscape. The model range includes machines of three traction classes, seven modifications, with an operating weight from 10.6 tons to 16.7 tons. Bulldozers are equipped with four-stroke diesel engines‚Turbocharged and direct fuel injection.

The undercarriage uses multi-roller track bogies with 6 - 7 rollers. The use of advanced materials processing technologies can significantly increase the service life of the products, as well as significantly reduce the time spent on adjustments.

Bulldozers are equipped with three types of blades - hemispherical, straight and swivel, as well as parallelogram-type ripping equipment with a single or three-shank ripper with a ripping depth of up to 650 mm.

Much attention is paid to ease of control and operator comfort - the cab glazing area is increased by 1.5 times. The rational installation of lighting devices has increased the duration of the machines by 20%.

ChTZ has developed and manufactured a prototype tractor under the brand name T2000 with bulldozer-loosening equipment and hydrostatic transmission from Saxengydravlik.

OJSC "Promtractor" is the largest manufacturer of powerful equipment used to perform heavy excavation work in industrial, road, oil and gas and hydraulic engineering, overburden in the mining industry, irrigation - in agriculture‚As well as for carrying out plantation, land reclamation and rescue operations and laying oil and gas pipelines.

The nomenclature of the currently manufactured products includes crawler bulldozers-rippers of 9 modifications (depending on the type and power of the engine), weighing from 28 to 95.5 tons. All of them are equipped with engines of the Volgograd and Yaroslavl plants, as well as the Cummins company (USA ).

Bulldozers are equipped with hemispherical blades and a single-shank parallelogram ripper.

The semi-rigid undercarriage consists of two tracked bogies that are pumped on the axle of the final drives. Back-up, carrier rollers and idler wheels with one-time lubrication for life with self-tightening type seals DUO-CONE.

The tensioning of the track chain is facilitated by the use of a hydraulic tensioning mechanism installed in conjunction with the release mechanism. Track rollers: 14 (7 on each side). Number of carrier rollers: 4 (2 on each side). Lifetime sealed and greased pivot tracks with split master link.

The cabin is two-seater, mounted on rubber shock absorbers. Sound-absorbing upholstery ‚providing maximum visibility‚ a large area of \u200b\u200bglass with double-glazed windows ‚excluding icing of the glass‚ a sprung seat adjustable for individual weight and height of the operator ‚a ventilation unit with a heater provide the operator with a comfortable working environment. Equipped with an independent diesel heater.